People use concrete sealers to provide protection for their floors against a range of potential harm. This includes surface damage, corrosion, staining, and chemical intrusion. One of the main culprits behind surface damage is moisture intrusion. In addition to this, these concrete sealants also offer protection against damage. Damage caused by adverse weather conditions, alkali-silica reactions, and corrosion. When you choose to utilize concrete sealers and follow proper maintenance routines, you can effectively guarantee the long-lasting beauty and extended lifespan of your surfaces.

When selecting a concrete sealer, there are three main factors to consider: location, size, desired finish and cost of installation. The location of your project will largely determine which type of sealer to use, as different sealers are better suited to address different conditions such as moisture, porosity, shine, and abrasion resistance. The size of your concrete surface will also influence how much sealer you need, as most products specify the square footage per gallon per coat. Finally, the desired finish of your project is an important factor to consider, as sealers not only protect your concrete stain but can also highlight the color and shine.

We know price is a factor so before we get too deep lets take a look at cost:

5000 square feet of clear acrylic sealer over bare concrete will range from $1.00-$2.00 per square foot while an epoxy or polyurethane in that same space might be $1.75-$3.00 depending on condition of the surface, moisture and location and other factors including how many coats are needed.

Film-forming sealers are available in three different types: Acrylic, Polyurethane, and Epoxy; each have unique benefits, while providing a gloss or sheen to the surface of the concrete.

Acrylic – Acrylic-based sealers are a cost-effective solution for adding a protective barrier to your concrete surfaces. Acrylic sealers are easy to apply, making them a great choice for DIYers, and their quicker dry time is perfect for projects on a tight timeline.

The use of polyurethanes as an interior/indoor sealer is the most popular choice and a smart environmentally friendly choice. Polyurethanes are harder than acrylic sealers and provide a thicker mileage making maintenance very low.

Understanding the different types of sealers for concrete

Film-forming and penetrating sealers

To keep decorative concrete or even plain looking attractive for a long time, we strongly recommend sealing with a high-quality concrete sealer. Once sealed, the concrete will be protected from grime, spills, and weather to help prevent any staining and reduce wear. Sealing for commercial and industrial environments that have high traffic is particularly important as it will ensure the surface can be easily maintained and kept looking good over a long period of time.

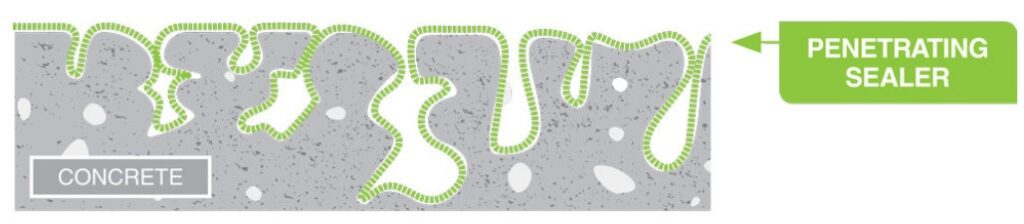

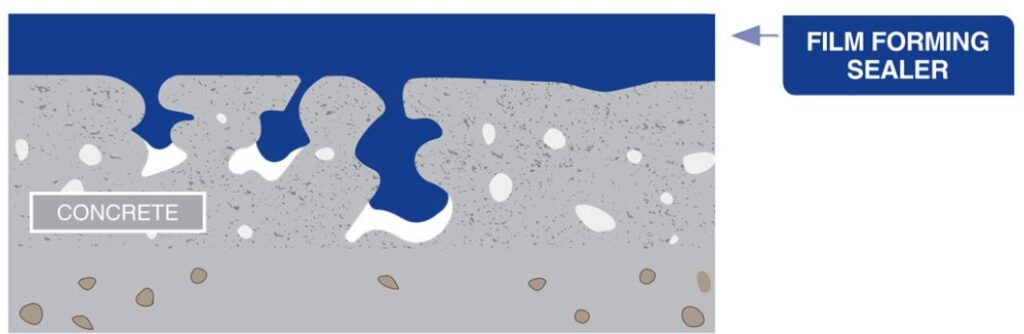

There are two common types of sealers to choose from – film forming and penetrating, with each offering their own different benefits and each suitable for different applications.

Film forming sealers

Film-forming sealers, also known as film-coating, surface-coating or topical sealers, coat the entire surface. The sealer adheres to the pores of the concrete and sits on top of the surface creating a protective layer. They offer excellent protection from moisture and spills, are highly durable, and are easy to maintain and reapply. There are three types of film-forming sealers, each designed for a specific purpose outlined below.

Acrylic sealers are commonly used for general protection from dirt and grime in both indoor and outdoor applications. They form a thin layer of protection on the concrete surface. Acrylic sealers are easy and quick to apply and tend to be the more cost-effective option, however due to their thin layer of protection they can wear more easily and require recoating. Available in both water-based and solvent-based formulations, they also come in a variety of sheen levels to enhance the surface color, stamped pattern, or exposed aggregate.

Polyurethane sealers provide a hard-wearing and non-yellowing layer of protection for both interior and exterior applications. They are a versatile sealer that can achieve a variety of gloss levels and can also be tinted. Commonly used in areas with high traffic, they also provide good protection against chemicals and abrasive materials. Polyurethane sealers are available in both water and solvent-based formulations to suit a variety of environments such as shopping centers.

Epoxy sealers are ideal for interior applications where durable and long-term surface protection is required. There is a range of epoxy sealers to choose from, each with its own list of benefits. For example, some have fast drying turnaround times for areas such as shopping centers or they can provide superior strength for industrial and commercial areas like car parks. The finish is glossy but if a more natural, matte finish is required, a matting additive can be added. Epoxy sealers can also be tinted.

To summarize, some of the benefits of using a film-forming sealer on concrete include:

Enhancing the color of your the surface

Preventing contaminants from penetrating the surface

Protecting the surface from damage and making it easier to clean and maintain

Protection from environmental elements

A range of products suitable for a myriad of applications

Examples of colored concrete with CCS surface coating sealers

The above examples demonstrate the same colored concrete before, (far left) and after treatment with different types of CCS surface-coating sealers.

Penetrating sealers

Penetrating sealers retain a natural-looking finish whilst protecting the concrete surface from water, stains and contaminants. These sealers penetrate into the capillaries of the concrete to form a long-lasting, durable barrier of protection against the ingress of water-borne pollutants and salts. Penetrating sealers are often used in indoor and outdoor applications for concrete, porous natural stone and concrete pavers.

General Purpose: Ideal for using on large commercial or industrial concrete areas to provide a good level of protection from general grime and spills.

Substrate Color Enhancement: An excellent choice where there is a need to bring out the color of the concrete whilst providing protection from an array of contaminants and stains.

Stain Blocking: Designed for public precincts, alfresco dining spaces and food service areas where there is a need for oil and staining resistance to food and drink spills.

Industrial Protection: Offering 3 way protection for industrial concrete substrates to prevent and assist dusting, wear and staining from oils and greases.

Considerations and common questions for sealing concrete

Can you seal new concrete straight away?

A sealer should only be applied after freshly laid concrete has been allowed to cure for 28 days.

Can you seal old or existing concrete?

You can seal existing concrete at any time and on multiple occasions. Sealing your old concrete can assist in restoring its appearance.

What are the signs that concrete needs to be resealed?

Water soaks into the surface instead of beading on top and the sealer appears dirty, scratched and worn

How often should you reseal your concrete?

It depends on the type of sealer, and the level of use the area gets. Sealer lifespans range from 1-10 years.

Will sealing the concrete change it’s appearance?

It depends on the sealer chosen – film-forming sealers tend to enhance the color and add a gloss; whilst penetrating sealers offer a natural matte finish. It is possible to use a colored sealer – this will guarantee a change to the existing color of the concrete.

What makes a good sealer?

A good sealer will prolong the life of your concrete, enrich and preserve the appearance, provide protection against contaminants, stains and moisture, and make it easier to clean and maintain your concrete. The best sealers do all the above and are breathable, which allows any moisture and air to rise to the surface of the concrete and escape.

To ensure decorative concrete lasts a long time and remains attractive, it is essential to seal it. The benefits range from protecting the surface and preventing stains to reducing the cleaning and maintenance required. Sealers and coatings also make it much easier to clean any stains or grime from the surface.

Is it better to spray or roll on concrete sealer?

The answer depends on the surface’s square footage. For large surfaces such as commercial floors, a sprayer is faster and way more efficient. Finally, for small surfaces, such as garages or any other exterior surface, a paint roller or any other type of roller will do the trick. Rolling is a less expensive process.

Can you seal concrete over old sealer?

Generally speaking, in most cases, a new solvent-based concrete sealer can be applied to a surface previously sealed with a solvent-based concrete sealer; however, it cannot be applied over a surface previously sealed with a water-based concrete sealer.