High Solids Epoxy Products Explained:

When shopping for a premium product in the epoxy world an important question to ask is: “What is the solids content?”

Epoxy is often described as being either 100% solids or low solids or some variation of this. What this means is that when the product is applied and then cured the thickness of the product that remains after it is cured defines it’s solid content. For example, when you paint your house with regular house paint the paint is partially composed of water so when you apply it to the wall and the water evaporates out of it and it dries; what you are left with are the “solids”. Epoxy is similar, when you apply 10 mils of 100% solids epoxy you are left with 10 mils of epoxy after it is cured. With epoxy you are not waiting for water to evaporate out for it to dry, you are waiting for the molecular structure of the compound of parts A & B to change..as those molecules bump into each other they change or “cure” similar to the process of plastic hardening. Now, if you apply 10 mils of a low solids epoxy (30% solids) then you are left with 3 mills of epoxy.

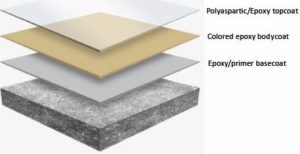

The higher the solids content the purer the epoxy. For optimal installations (based on a solid color) you would want 1 coat of Primer Epoxy, 1 Coat of 100% Solids Epoxy and a Top Coat of UV resistant epoxy. Some companies describe epoxy and urethane as “Industrial Grade”. There is no actual product that is “industrial” grade from the manufacturer. The term “Industrial Grade” is more a descriptive used to let the customer know they are getting a floor coating system that is intended for industrial use.