Epoxy vs. Urethane

See more photos on Google

or check us out on Facebook

Our System: As a general rule, most of our floor coatings start with an epoxy primer, then add an intermediate coat of epoxy and then when needed, a top coat of urethane is applied. Epoxy is thicker than urethane so broadcast mediums (such as flake, chip or quartz) are generally applied to epoxy rather than urethane.

Epoxy is available in clear as well as an array of other colors. Epoxy floors are seamless. Their application process requires a wet edge application; therefore, repairs are seldom applied without some degree of visibility.

Epoxy is a thermosetting polymer which is available in three different formulations for a floor coating and sealer; water based, solvent based, and 100% solids.

“100% Solids” epoxy is a term used to describe the volume of solids in a coating system. It’s what is left over after the epoxy floor paint coating dries or “cures”. 100% solids will yield 100% dried material after the floor coating fully cures. For instance, 50% volume solids will yield 50% of the thickness after the floor coating fully dries/cures. Most water-based epoxies are 30% to 40% volume solids. With an epoxy, you are not waiting for water to evaporate out of it in order for it to dry like you do with paint. With epoxy you are waiting for the molecular structure to change causing the product to harden or “cure”.

In the opinion of Slip Free Systems the best epoxy formulations are 100% solids. This provides for an extremely hard, thick, and impact resistant surface. That opinion is based on a standardized idea of what a cement slab should be. Not all slabs are created equal so different products might be a better solution for different jobs. Factors such as vapor transmission, the ground water table, texture of the surface, contaminants and other environmental factors all affect the final finish and longevity.

With a properly prepared floor you no longer worry about hot tire pick up, scratching, and wear from abrasion. Though some epoxy formulas come with U.V. inhibitors, they will still eventually yellow or amber when exposed to sunlight for any length of time. When an epoxy manufacturer says their product is UV resistant, you can loosely compare it to the SPF of sunscreen. Theoretically, the higher the number the more protection. With epoxy there are no variable degrees of protection so this promise of UV resistance cannot be relied on for optimal performance.

Some projects require urethane because it is much more resistant to ultraviolet light than epoxy. Ultraviolet light is one of the factors that contribute to the products changing of color also known as “ambering”. Since urethane is UV resistant, the color of the product will remain the same for a longer period of time than when epoxy is used. Epoxy is not resistant to ultraviolet light so the products with epoxy often change color or amber over time. Thats a definite plus for urethane and polyurethane products.

It is said that epoxy offers higher strength than urethane when tested for tensile strength. When applied to surfaces, the epoxy component keeps them from moving. However, the epoxy substance can easily crack if it is applied to surfaces that require partial or frequent movement such as an elevated ramp or a ships deck. In other words, a standard 100% solids epoxy is not good to use on surfaces that inevitably need movement. As with most product lines, our manufacturers have products that are specially formulated for specific industry needs.

BENEFITS

Environment

Cracked floors and trenches may allow hazardous chemicals used in your facility to seep into the ground below. Not only is this environmentally unsound, but it may also violate EPA regulations. Slip Free Systems can repair and coat your concrete so that chemicals neither seep through, nor damage, your concrete.

Longevity

Cracking and pitting are certain signs that your concrete is aging. Once they begin, they hasten the deterioration of your floor. Slip Free Systems repairs and protects your concrete with a coating it adds years to its life expectancy.

Cleanliness

In many warehouses, quality control depends on strict standards of cleanliness. Concrete dust can make meeting these standards almost impossible. Slip Free Systems can repair or replace your existing slab, then coat it to prevent concrete dust and optimize production. This makes cleanup easier in any facility.

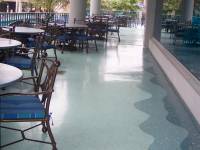

Aesthetics

Let’s face it – stained, cracked concrete floors just don’t look good, especially if this is an area your customers can see. But, even if it isn’t, the appearance of your facility is, to your employees, a reflection on how you view your business. Slip Free Systems promises an attractive result. A properly coated floor is clean, level and light reflective. You, your customers, and your employees will be amazed at the difference!

Safety

Employees are far more likely to suffer trips, slips, and falls if your floor is cracked, pitted, or uneven. If this is a public area of your facility, your customers might injure themselves, as well. Slip Free can provide the solution. Repairing and leveling your floor will make it safe for your customers and employees. Coating it with a textured, skid resistant epoxy will further enhance your floor’s safety.

At Slip Free Systems we are always concerned about safety. Using our English XL Tribometer we are able to measure the slip resistance of your existing floors and your new slip free floor after installation. You can rest assured that your new slip free floor meets OSHA and ADA standards.

General Polymers Standard Color Chart

For more photos of our work check out Google, Facebook, Houzz, Yelp, HomeAdvisor or Thumbtack.

Click here to return to our home page.