Deciphering the different types of coatings. How to choose from Marbled Metallic, Full Flake (Faux Granite), Glimmering Mica or Industrial Solids.

Industrial & Marine floor coatings are generally a solid color with an optional urethane topcoat.

Other options include yellow or red striping and color-coded isles and workstations.

Residential & Commercial floor coatings are generally more decorative utilizing the wide array or color and texture options offered with chip, flake, quartz, mica or metallic.

Below, you will find a sample of each and a link for more information.

Check out our Google Pics for even more images.

Chip or “Flake” floor coating:

Chips come in a wide array of solid colors which can be blended to create millions of formulas to match literally any décor. These flakes also come in sizes so you can also customize the texture and busyness of the pattern. These chips are also available in a shimmering mica option for a opalescent appearance.

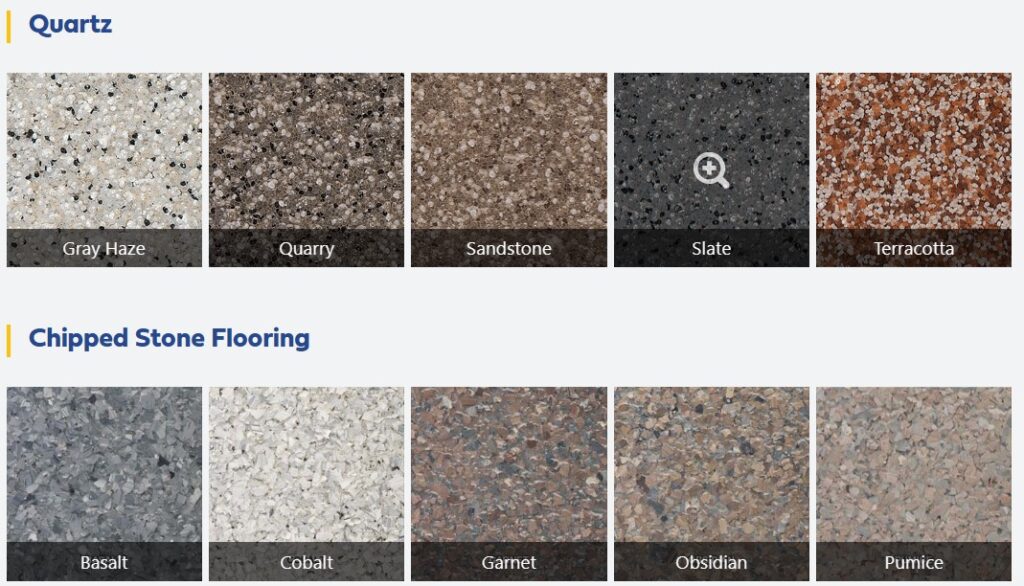

Quartz Coatings: (or visit our page for epoxy quartz flooring)

Quartz floor coatings are basically tiny little particles of sand that have been ceramic dipped and heat treated to add color and when broadcast into epoxy create a beautiful seamless floor with a non slip texture. Quartz floor coatings are a great high build option for really rough concrete or for high traffic areas that need that added boost of durability.

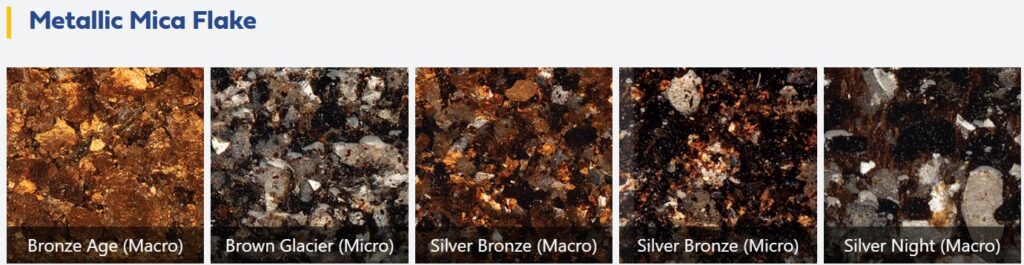

Metallics: (or visit our page for Epoxy Metallic Floor Coatings)

Marvelous Metallic Floor Coating

Metallic floors are relatively new to the industry and are quickly taking the place of concrete stains with their flawless marbled finish and shimmering appeal.

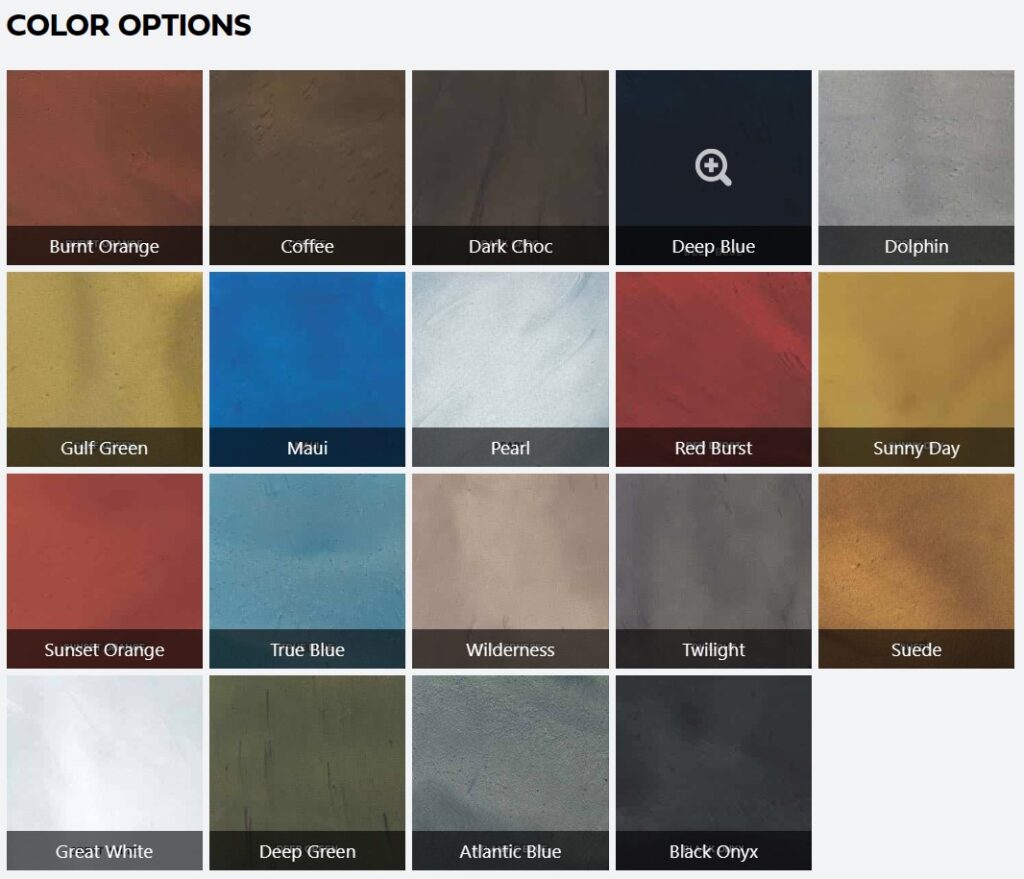

Solids:

Choose from any of our many colors for a solid color surface that fits your needs. Add free optional non-skid for the perfect non slip texture.

Concrete Stains: (or visit our page for Concrete Stains and Sealants)

Stains offer a natural appeal. Stains are translucent and bring out the beauty of a concrete floor by adding a transparent color and shine to the floor. Stains come in 16 colors. Stain color can not be matched perfectly due to their dependence on chemical reactivity to elements in the slab and their natural tendency to marble and flow with dark undertones and pale highlights.

Polishing: (or visit our page for polishing)

Polishing is a great option often specified for its reputation to be low maintenance. A common misconception is that a polished floor gets is shine from being ground down to a superfine finish using multiple passes with floor machine. It is true that the floor gets its smooth finish from grinding, the actual shine comes from a polishing compound and over time will require some maintenance to maintain the shine.

Other options:

Electrostatic Dissipative Floors

Digital Imaging

Expansion Joint Treatment

Floor Leveling and Repair

Crack Repair

Fast Curing MMA (Methyl Methacrylate)

Our floor coatings have the added benefit of USDA approved antimicrobial additive for an optimal floor finish in the food and drug industry.

Standard Marbled Metallic Options:

Standard Solid Colors